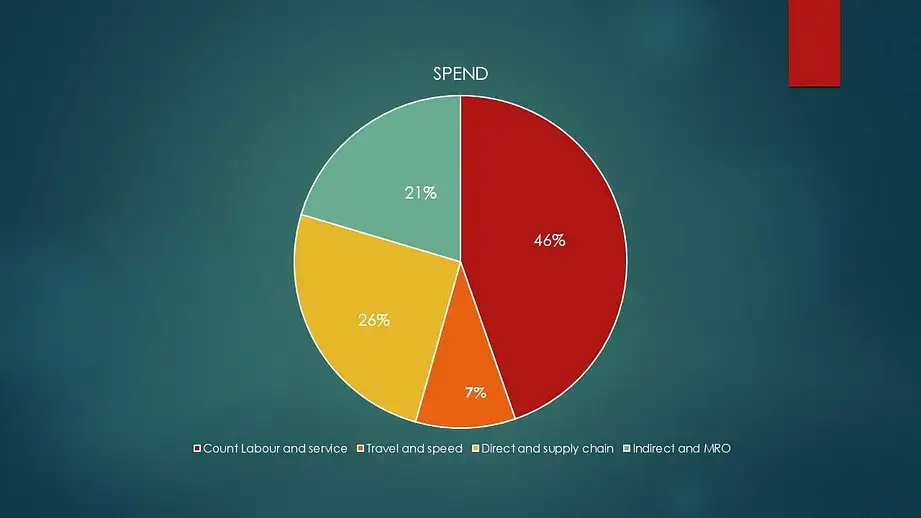

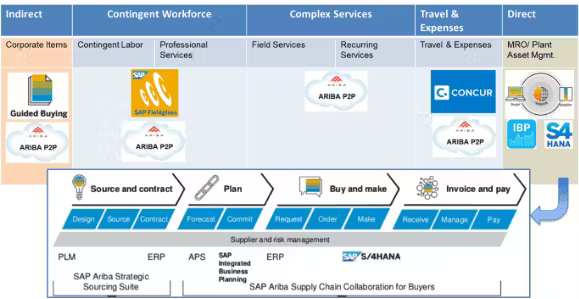

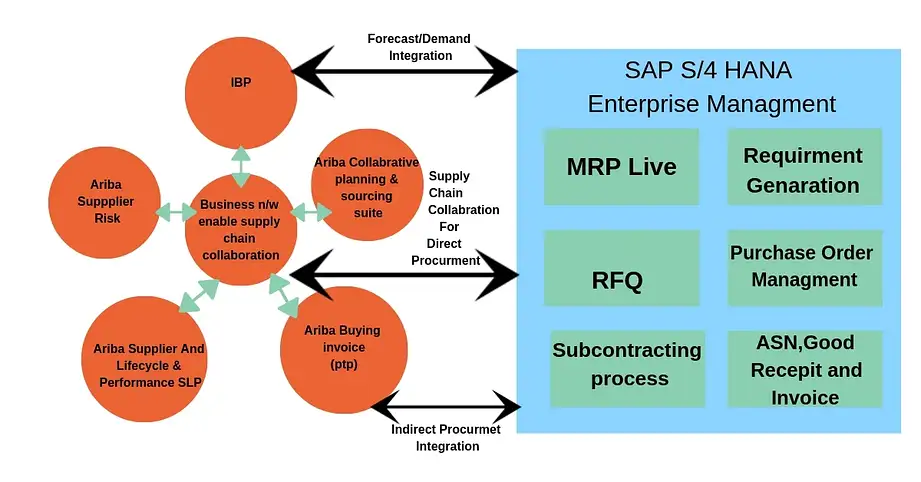

It also discusses the planning collaboration through integration between SAP IBP and Ariba Network in order to arrange the supplier with visibility of the forecast. For particular business sections such as automotive, manufacturing, defence and so on, direct procurement pay is one of the fastest places. Corporations belonging to the Corporations Area Unit seeking a unified resolution that clogs up all pay at the expense side of Direct, Indirect and Services. Direct pay is one of the top items and P&L of corporations. Low pay matrix is indicative pay but shows the direct pay of 26% a serious chunk that has got to be brought below overall pay management.

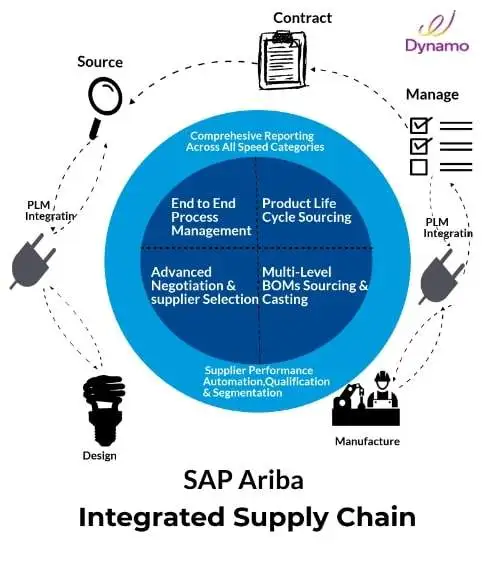

Sap as product company for sap ariba solutions accepted this need and commenced to incorporate the missing things of direct acquisition. This addresses the Direct Sourcing want mix between SAP Ariba Sourcing & PLM. additional it addresses plans partnership of the integration Combining the Ariba Network and SAP IBP to give permeability of the figure to the provider. Supply Chain Collaboration (SCC) on the other hand provides the visibility of Subcontracting process from issue of basic material to manufacturing status of goods and receipt of finished good.

SAP included the direct sourcing function whereby the PLM/ERP system will be coordinated with sap Ariba sourcing to get the demands from detonated BOM. All such necessities will at that point be sourced by utilising Ariba sourcing & remainder of the procurement method are followed in Ariba or SAP side.

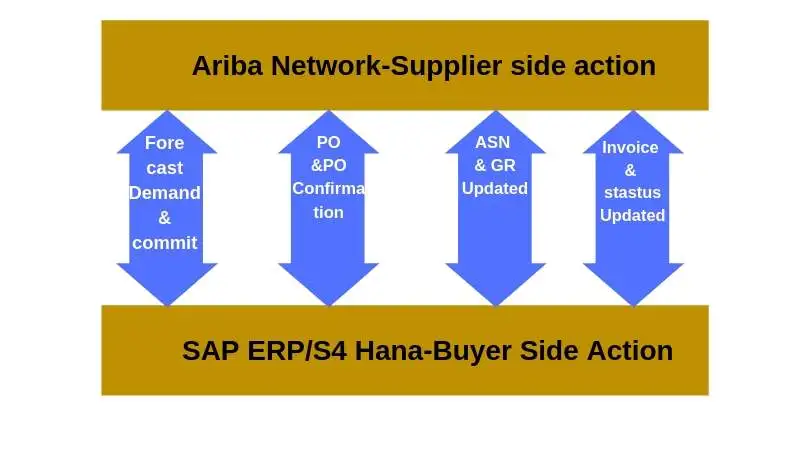

ERP arranging frameworks getting incorporated to ASN to get the submit from provider over designing forecast to verify future receipt else on uncertain interest,organizer can make advance move to keep away from supply disturbances.

Here two main categorise for direct planning/procurement in SAP Ariba by integrating with ERP:-

Direct material sourcing:-

Leverage extant Ariba Sourcing application with Quote to RFX Functionality. (Integration -ERPs<> Ariba Sourcing) and Product Sourcing with BOMs and Quote Automation.

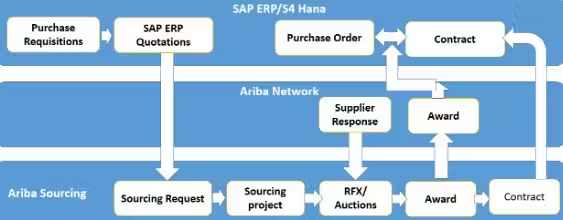

Two ways to sourcing the direct material

- Making of Sourcing request > Sourcing project > RFX and Contract > Contract to ERP

- Making of Quote from PR> Quotation > Quote > Contract/PO

Supply Chain Collaboration (SCC):

Extending procurement for Forecast / demands of Direct Materials. (Integration –ERP Planning system/IBP <> ASN) to induce well timely Forecast commitment from vendors on ASN therefore the coming up with may be realistic as per business demand and indications to planner for any glitches in provide chain to require various action in time to avoid provide disruptions.

Let’s look at these two main areas in detail and how they meet the requirements for direct spending.

- Ariba Collaborative Supply Chain (CSC):

Sap ariba is repeatedly doing developments for maximum use of B2B network(ASN)

Cloud offers improved visibility and clarity overall supply chain for direct materials for discrete and manufacturing process and pharma/life sciences, consumer goods etc.

Ariba cooperative offer supply Chain is for quicker and successful joint collaboration with suppliers and commercialism partners and not about to replace the present infrastructure of IBP, APO or SAP ECC planning engine.

SAP Ariba solutions offer Chain Collaboration (CSC) for consumers & suppliers has main benefits for Businesses as:

- Improved visibility.

- Online and context specific Communication.

- collaboration among offer chain partners.

SAP Ariba provide stand out direct material and supply chain coordinated effort tools for consistent associate between all organisation and partners to a typical arrangement so they can all the more likely organise multi-level supply chains and decrease stock. Supported situation incorporate procedures for subcontracting, estimating, distribution, just as returns.

SAP Ariba Document Automation And Collaborative Supply Chain(CSC)-Basic Scenario:-

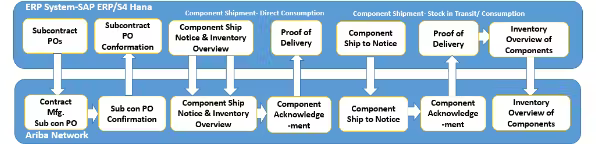

Contract Manufacturing Collaboration (Subcontract PO) for Direct Materials:

They are many stages in contract construction subcontract produced to be allowed as per the good practices in procurements. Basic state of affairs that was promoted in typical ERP currently will be integrated SAP Ariba ASN as central ‘subcontracting purchase orders’ with parts, ‘purchase order supporting’, and ‘ship to’ notice of finished product(ASN) to the client. the client sends a product receipt and invoice to the provider.

In adding to basic subcontracting, method permits buyers/suppliers to observe part shipments/deliveries. Basic shipments square measure supported also as clarity of part inventory and part acknowledgement. There square measure 2 completely different choices for part shipments.

One-step method: during this process each the ship notice request and material Action message are sent in a very single step. The verification of delivery is triggered at the provider aspect once the parts are received.

Two-step method: Overall steps area unit constant because the One-step method process, the primary change is once these method are taken. The two step method waits for the to be received before the production is captive into the customer system, and a product activity message is triggered.

Final production: Suppliers on AN with SAP ERP have choice to intimate client concerning production of the finished product via producing execution system (MES) visibility. Messages are typically triggered from finished production orders within the provider system and sent to tell the customer of how much finished product has been made.

Real time consumption:-period of time consumption is once the provider goes through the elements initially dispatched by the customer and so notifies them. Once the customer receives the notification, a item activation message is distributed to the provider from SAP with current part quantities as SAP must be the system of record..If period computation isn’t used, then the merchandise activity message for part summary is distributed once merchandise the products} receipts from the ship notice of finished goods is distributed.

The following illustrates typical contract producing method flows at the side of consumption and execution visibility at the element level:

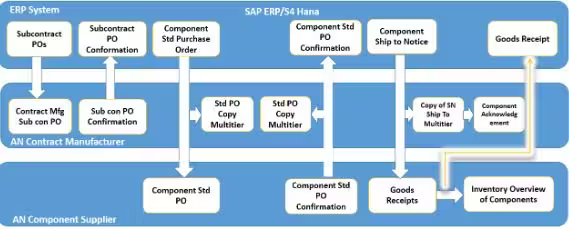

SAP Ariba doesn’t stop for less than Subcontracting methodes however has Multi-tier Subcontracting produce that is back to theThird Party command or Drop Ship system in standard ERP terminologies.

Multi-level Contract Manufacturing Collaboration Support – Multi-level Subcontracting:-

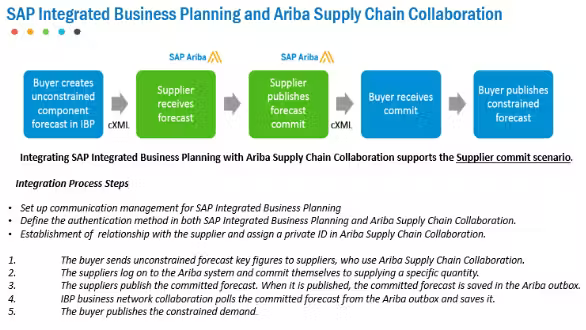

Integrated Forecast Collaboration-

Collaboration with forecasts offers the supplier with several advantages. First, by offering suppliers with near – real – time accessibility in demand forecasting, it enables them to more effectively schedule procedures and plan the use of capacity to meet the specifications of the buyer.

This also enables vendors to commit against the predicted quantities requested by the purchaser, which can then be spaced to procedures in the planning of material requirements (MRP) software of the purchaser.

SAP Ariba with Direct Material Sourcing: –

SAP Ariba is valuable for Direct Material Sourcing events where the the Sourcing Request originates in the ERP system and is transferred to to a three – dimensional SAP Ariba Sourcing

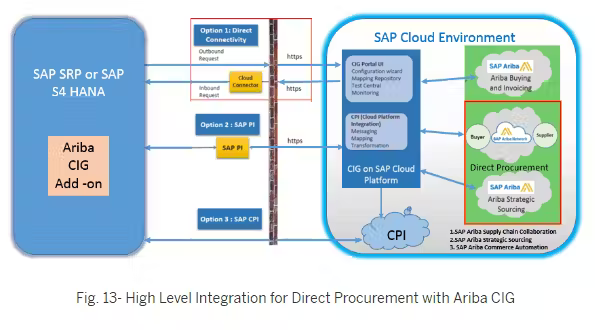

SAP Ariba Strategic Sourcing integration with SAP ERP or SAP S/4HANA is actualized when a client needs to deal with their operational procurement process inside their SAP ERP or SAP S/4HANA cloud services independently from their strategic procurement method in SAP Ariba Sourcing.

Sourcing for direct Procurement:-

With ongoing improvements by way of SAP, now it’s viable for construction of Sourcing Request from the Quotations in back finish ERP approach which trigger SAP Ariba to create sourcing tasks on BOM and substances.

Using of sap ariba direct material sourcing procurement

- Product Sourcing

- Quote Automation

Here the details for

1.Product Sourcing

SAP Ariba is expanding its Product Sourcing available for support:

Project for full procurement of materials and BOMs for quotation requests from Product Sourcing

Sourcing of materials and BOMs for Product Sourcing requests

Users can now automate repetitive templates for direct material sourcing as permitted and use them in Product Sourcing.

Initially, in order to receive price quotes, sourcing managers using the Product Sourcing dashboard tab were restricted to using simple RFX events. Buyers were therefore unable to use the features available in other types of events, such as thorough RFPs and auctions.

Buyers may also start collecting pricing structure throughout all BOMs for materials with a total value based on the quality of BOM.

SAP Ariba immediately purchases historical prices, quantity, supplier – highly specific prices and conditions with supplier – specific values to the sourcing project when buyers generate product sourcing projects. SAP Ariba also involves adding AML suppliers from product sourcing Also as hired suppliers in the sourcing project.In Product Sourcing, buyers can also start searching for extra items and add those other raw materials to their sourcing events. Buyers can accept cost structure during the process of awarding the entire event and the info will be returned to the sourcing of the product.

This key feature of Sourcing allows you to:

- Purchase projects from the BOM Settings tab

- Generate projects from sourcing materials

- award events

- save pricing to the pricing database

2. Quote Automation (Automated RFQ processing):

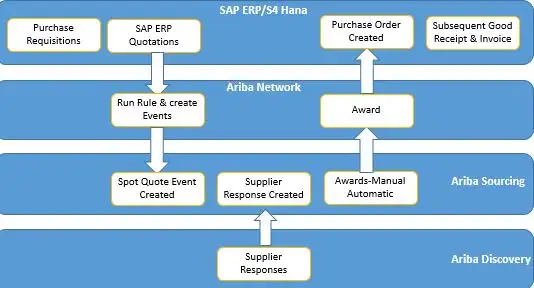

Quote automation gives a direct integration between the buyer’s ERP system, Ariba Network, and SAP Ariba Discovery to easily build and publish tactical Quotation Request (RFQ) events and pick up suppliers ‘ bids. The purchaser has the option of comparing and awarding these quotes in the solution or exporting all bids in the ERP. An RFQ is sent directly via the SAP Ariba Cloud Integration Gateway to Ariba Network and from there to SAP Ariba Sourcing as a request for sourcing. Based on the header data sent from SAP ERP or SAP S/4HANA, the sourcing request is routed to the appropriate sourcing manager.

The sourcing manager is informed of reviewing and editing the sourcing request and sending it for approval if necessary, and then creating a sourcing project based on the most suitable template.

Ariba Spot Quote Integration with SAP ERP and S/4 HANA:-

Starts with the SAP system when a a subscriber generates a RFQ (Quotation Request) from a purchase or scratch request. Subscribers enter open and close and dates of events and specify entries with groups of materials and plants delivering them.

The RFQs were sent to Ariba Network and then on to Ariba Sourcing through the Ariba Network Adapter for SAP PI, which generates and submits an RFQ incident instantly on Ariba Discovery. Vendors can either be hired to the Spot Quote event or adjusted on the basis of products and services classifications and location through Ariba Discovery. If an invited supplier is not approved with Ariba Network, they will automatically generate an Ariba Network account.

SAP Ariba Agreements needs to send contract relevant information such as the contract header data and line item data to sap support solutions or SAP S/4HANA when a purchaser submits a contract. SAP ERP or SAP S/4HANA then generates a draft agrement based on the contract information collected from SAP Ariba Contracts.

Service Items Integration with Service Hierarchies in RFQs to Quote:-

With support from service hierarchies, the supply of service items has been enhanced. Buyers using the SAP Ariba Sourcing and SAP Ariba Agreements can make multiple provider items up to five – level structure (one parent item and four – level at least child hierarchy) to of their own SAP back end systems integration flow from such an RFQ. Vendors using SAP Ariba Sourcing and SAP Ariba Agreements can add several service items with up to five – level hierarchy to to the integration flow from an RFQ in their SAP back – end system to to a SAP Ariba sourcing request, SAP Ariba award to PO and outline agreement, and SAP Ariba contract to outline agreement in their SAP back – end system.